Dubai

Rheology Modifier

In the polymer compounding industry, they use different additives to achieve their desired goals and specifications. One of these additives is rheology modifiers. You can see two different grades of our rheology modifiers in the table below.

| Business Type | Exporter, Supplier |

| Application | Industrial |

| Country of Origin | UAE |

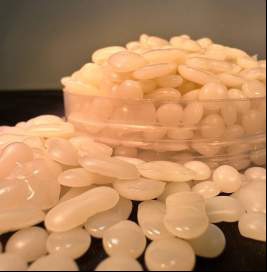

| Physical State | Granuels |

| Color | White |

| Storage | Keep in a Cool Dry Place |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

Introduction

OKAPRO-200 is a dispersing agent, lubricant and viscosity reducer for use in the formulation of all kinds of hot melt adhesives, compounds and polymer masterbatches, which adds suitable properties to your final product according to its properties.

Industry

- Polymer Compounding and Processing Industry

- Hot-Melt Adhesives Industry.

- Wire and Cable Industry.

Application

Used in different plastics masterbatches and compounds as dispersing agent and lubricant additive.

Advantages

* Good lubrication properties

* Optimal coupling properties

* Good thermal resistance

* Setting and controlling open time and set time

Recommendedation

Recommended using this masterbatch with a dose of 1.5-5%, depending on the final product and processing conditions. You can contact our experts for proper use and better formulation.

Storage

Product properties will change minimally under the following storage conditions:

* Ambient temperature (25-35 °C)

* Away from fire

* Dry place

“ on the pallet

| Business Type | Exporter, Supplier |

| Application | Industrial |

| Country of Origin | UAE |

| Physical State | Granuels |

| Color | White |

| Storage | Keep in a Cool Dry Place |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

Introduction

We have developed an efficient one pack dispersing agent/coupling agent/ lubricant additive as trade name OKAPRO400 to be used in different plastics masterbatches and compounds. By using this additive alone you can eliminate any coupling agent and lubricant in your formulations. This additive in granule form and dust-free and very easy handling.

Industry

- Polymer Compounding and Processing Industry

- Hot-Melt Adhesives Industry

- Wire and Cable Industry

- Textile industry

Application

Used in different plastics masterbatches and compounds as dispersing agent/coupling agent/ lubricant additive

Advantages

* Good lubrication properties

* Optimal coupling properties

* Good thermal resistance

Recommendation

Recommended using this masterbatch with a dose of 1.5-10%, depending on the final product and processing conditions. You can contact our experts for proper use and better formulation.

Storage

Product properties will change minimally under the following storage conditions:

* Ambient temperature (25-35 °C)

* Away from fire

* Dry place

* on the pallet