Dubai

Polymers

Leading Exporters, Wholesaler and Manufacturers of Hot Melt Adhesive, Booster and Cleaner of Hot-Melt Adhesive, Polymer Masterbatch and Rheology Modifier from Dubai.

| Business Type | Exporter, Supplier |

| Color | Transparent |

| Application | PVC Edge Banding |

| Packaging Type | Packet |

| Type | Hot Melt Adhesive |

| Country of Origin | UAE |

| Grade Standard | Industrial Grade |

| Material Compatibility | Paper |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

| Business Type | Exporter, Supplier |

| Material | Plastic |

| Form | Granuels |

| Country of Origin | UAE |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

Technical Data Sheet

Introduction :- There are different grades of hot melt adhesives in the market that may have different qualities, so we at Okam Polymer Asia started producing OKAMaxx-3000 to increase the properties of hot melt adhesives that are of poor quality. This product can also help you as a strong cleaner in situations where adhesives ket stuck or burned in the tank or nozzle of the device. Woodworking Industry

Industry :- Woodworking Industry

Application :- Hot-melt adhesive booster and cleaner for PVC edge banding machines

Advantages :-

- Increasing glue fluidity

- Reducing glass transition temperature

- Enhancing adhesives and providing better coverage of the desired surface

- Enhancing adhesives and providing better coverage of the desired surface

- Cleaning of edge banding machine

- Increasing softening temperature for better performance in tropical regions while preventing condensation

Recommendation :- When this product is used as an improver for hot melt adhesives, its consumption can be from 10-30% depending on the quality of the adhesive used. If it is used as a cleaner, pour it pure into the device to remove the burnt adhesives. You can contact our experts for more information.

Storage :- Product properties will change minimally under the following storage conditions:

- Ambient temperature (25-35 °C)

- Away from fire

- Dry place * on the pallet

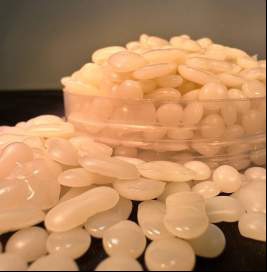

| Business Type | Exporter, Supplier |

| Color | White |

| Condition | New |

| Application | Indusrtial Use |

| Packaging Type | Poly Bag |

| Type | White Masterbatches |

| Country of Origin | UAE |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

Introduction

OKAColor-PE900 is a polyethylene masterbatch filled with titanium dioxide. This white masterbatch can be filled with 40 to 70%wt (OKAColor-PE940, OKAColor-PE950, OKAColor-PE960, OKAColor-PE970). Titanium dioxide depends on the application and quality of the final product and the customer's needs. This masterbatch is used in various application-forming processes.

Industry

Polymer Compounding and Processing Industry

Application

Water containers - PE packaging films - Shopping bags - Injected parts.

Advantages

* Providing significant cost reduction

* Improving productivity & performance

* Excellent dispersing

* Excellent compatibility with the raw material

Recommendation

Recommended using this masterbatch with a dose of 1-20%, depending on the final product and processin conditions. The processing temperature is set according to the resin’s processing temperature.

Storage

Product properties will change minimally under the following storage conditions:

* Ambient temperature (25-35 °C)

* Dry place

* Away from fire

* on the pallet

| Business Type | Exporter, Supplier |

| Application | Industrial |

| Country of Origin | UAE |

| Physical State | Granuels |

| Color | White |

| Storage | Keep in a Cool Dry Place |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

Introduction

We have developed an efficient one pack dispersing agent/coupling agent/ lubricant additive as trade name OKAPRO400 to be used in different plastics masterbatches and compounds. By using this additive alone you can eliminate any coupling agent and lubricant in your formulations. This additive in granule form and dust-free and very easy handling.

Industry

- Polymer Compounding and Processing Industry

- Hot-Melt Adhesives Industry

- Wire and Cable Industry

- Textile industry

Application

Used in different plastics masterbatches and compounds as dispersing agent/coupling agent/ lubricant additive

Advantages

* Good lubrication properties

* Optimal coupling properties

* Good thermal resistance

Recommendation

Recommended using this masterbatch with a dose of 1.5-10%, depending on the final product and processing conditions. You can contact our experts for proper use and better formulation.

Storage

Product properties will change minimally under the following storage conditions:

* Ambient temperature (25-35 °C)

* Away from fire

* Dry place

* on the pallet