Dubai

Polymer Masterbatch

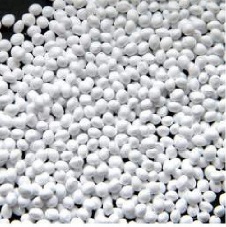

Masterbatch is a thick mixture that includes three components; polymer, additive, and a compatibilizing and dispersing agent. Additives masterbatch are large quantities of colored powders (pigments), inorganic fillers, or chemicals that are added to the polymer for three different purposes, including producing color, improving properties, or reducing cost. The polymer masterbatch base should usually be similar to the original plastic used and have a granule appearance. Types of masterbatches according to their tasks include color masterbatches, additives, and fillers. At Okam, we produce all kinds of masterbatch, including filler, white masterbatch, improved mechanical properties, flame retardant, etc., and we introduce our two types of white masterbatch and filler in the table below.

| Business Type | Exporter, Supplier |

| Color | White |

| Condition | New |

| Application | Indusrtial Use |

| Packaging Type | Poly Bag |

| Type | White Masterbatches |

| Country of Origin | UAE |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

Introduction

OKAColor-PE900 is a polyethylene masterbatch filled with titanium dioxide. This white masterbatch can be filled with 40 to 70%wt (OKAColor-PE940, OKAColor-PE950, OKAColor-PE960, OKAColor-PE970). Titanium dioxide depends on the application and quality of the final product and the customer's needs. This masterbatch is used in various application-forming processes.

Industry

Polymer Compounding and Processing Industry

Application

Water containers - PE packaging films - Shopping bags - Injected parts.

Advantages

* Providing significant cost reduction

* Improving productivity & performance

* Excellent dispersing

* Excellent compatibility with the raw material

Recommendation

Recommended using this masterbatch with a dose of 1-20%, depending on the final product and processin conditions. The processing temperature is set according to the resin’s processing temperature.

Storage

Product properties will change minimally under the following storage conditions:

* Ambient temperature (25-35 °C)

* Dry place

* Away from fire

* on the pallet

| Business Type | Exporter, Supplier |

| Color | White |

| Application | Indusrtial Use |

| Packaging Type | Plastic Bag |

| Type | White Masterbatches |

| Country of Origin | UAE |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

Introduction

OKAColor-PP is Titanium Dioxide filled polypropylene masterbatch. This product can be filled with 40 to 70%wt (OKAColor-PP940, OKAColor-PP950, OKAColor-PP960, OKAColor-PP970). The percentage of titanium dioxide depends on the application and quality of the final product and the customer's needs. This white masterbatch is used in various applications and is designed for processing in various forming processes. This grade of fine white pigments in which the best dispersion and distribution of white pigments are provided in final products.

Industry

Polymer Compounding and Processing Industry.

Application

Water containers - PP packaging films - Shopping bags - Injected parts.

Advantages

* Providing significant cost reduction

* Improving productivity & performance

* Excellent compatibility with the raw material

* Improving printability of the polymeric parts

Recommendation

Recommended using this masterbatch with a dose of 1-20%, depending on the final product and processing conditions. The processing temperature is set according to the resin’s processing temperature.

Storage

Product properties will change minimally under the following storage conditions:

* Ambient temperature (25-35 °C)

* Away from fire

* Dry place * on the pallet

| Business Type | Exporter, Supplier |

| Color | White |

| Application | Indusrtial Use |

| Type | Filler Masterbatch |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

Introduction

OKAFill-PE is a calcium carbonate-filled polyethylene Masrbatch. This product can be filled with 50 to 80%wt (OKAFill-PE50, OKAFill-PE60, OKAFill-PE70, and OKAFill-PE80). The percentage of calcium carbonate depends on the application and quality of the final product and the customer's needs. This masterbatch is used in various applications and is designed for processing in various forming processes.

Industry

Polymer Compounding and Processing Industry

Application

Water containers - PE packaging films - Shopping bags - Injected parts

Advantages

* Providing significant cost reduction

* Improving productivity & performance

* Improving printability of the polymeric parts

* Excellent dispersing and compatibility with the raw material

Recommendation

Recommended using this masterbatch with a dose of 5-50%, depending on the final product and processing conditions. The processing temperature is set according to the resin’s processing temperature.

Storage

Product properties will change minimally under the following storage conditions

* Ambient temperature (25-35 °C)

* Away from fire

* Dry place

* on the pallet

| Business Type | Exporter, Supplier |

| Color | White |

| Application | Indusrtial Use |

| Type | Filler Masterbatch |

| Country of Origin | UAE |

Preferred Buyer From

| Location | United Arab Emirates, India, Kenya, Tanzania, United Republic of, South Africa, Turkey, Thailand, China |

Introduction

OKAFill-PP is a calcium carbonate-filled polypropylene Masrbatch. This product can be filled with 50 to 80%wt (OKAFill-PP50, OKAFill-PP60, OKAFill-PP70 and OKAFill-PP80). The percentage of calcium carbonate depends on the application and quality of the final product and the customer's needs. This masterbatch is used in various applications and is designed for processing in various forming processes.

Industry

Polymer Compounding and Processing Industry.

Application

PP packaging films - Shopping bags - Injected parts.

Advantages

* Providing significant cost reduction

* Improving productivity & performance

* Improving printability of the polymeric parts

* Excellent dispersing and compatibility with the raw material

Recommendation

Recommended using this masterbatch with a dose of 5-50%, depending on the final product and processing conditions. The processing temperature is set according to the resin’s processing temperature.

Storage

Product properties will change minimally under the following storage conditions:

*Ambient temperature (25-35 °C)

* Away from fire

* Dry place

* on the pallet